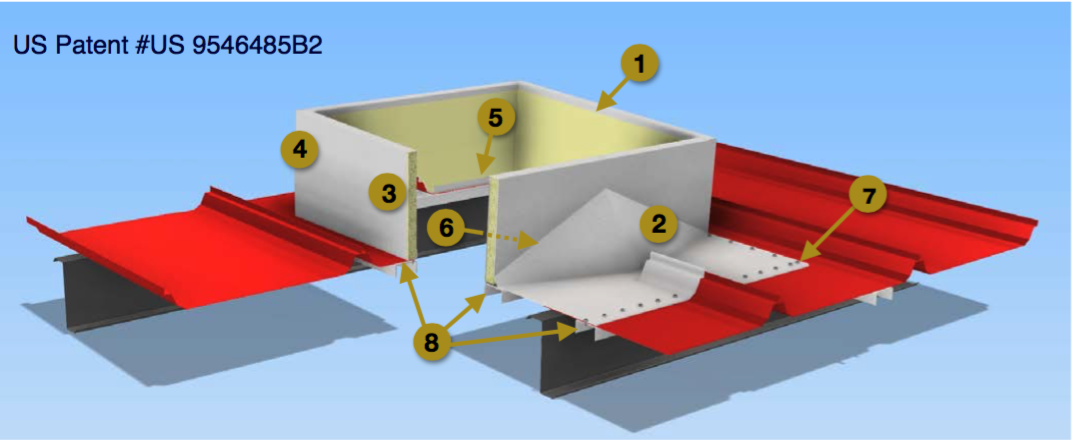

SSM offers a one-of-a-kind patented (US Patent #US 9546485B2) roof curb that comes in one piece with no assembly required making for easy install.

- 24 gauge Galvalume®, welded cap is part of our patented design.

- Integral water diverter cricket.

- Our components are 18 ga. Galvalume® or as project requires. Our standard Top Flange is 1 1/2” wide but this can vary depending upon your job requirements.

- Standard height is 10”and sloped to the roof pitch to provide a level mounting surface, based upon your project’s specific needs.

- The bottom flange, found on 3 sides, is also 1 1/2” wide but custom widths are available.

- The interior of the Cricket is full enclosed and insulated.

- Pre-laid out fastener holes, 9/32” in diameter, are placed at 3” [max.] centers around the full curb perimeter.

- 12 gauge panel support channels.

Engineered for ease of Installation, SSM‘s one piece hybrid curb solution is designed to make installation easy.

Engineered for ease of Installation, SSM‘s one piece hybrid curb solution is designed to make installation easy.

A] Set the curb in place and mark the area to be removed.

B] Cut the opening needed and trim back the roof’s standing seam components as needed for the curb to seat properly.

C] Clean the area around the opening to remove loose particles.

D] Apply double stick butyl tape [provided] to the underneath side of the perimeter of the roof curb.

D] Apply double stick butyl tape [provided] to the underneath side of the perimeter of the roof curb.

E] Trim all excess butyl and check to see that the tape is secure.

F] Remove the backing layer from the tape and flip the hybrid roof curb over – holding it above the roof opening – and check for proper alignment.

G] Place curb in position and press down along the butyl tape edges to ensure even contact.

H] Secure the curb in place, as per the provided fastener holes, with mechanical fasteners [provided].

I] Clean up the area around the opening joint between hybrid curb and roof to remove any loose particles.

I] Clean up the area around the opening joint between hybrid curb and roof to remove any loose particles.

J] Apply caulk around the perimeter of the hybrid curb in an even and concise manner, utilizing the proper tools, to ensure a consistent seal.

That is it! You are ready to move on to the next one!